Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

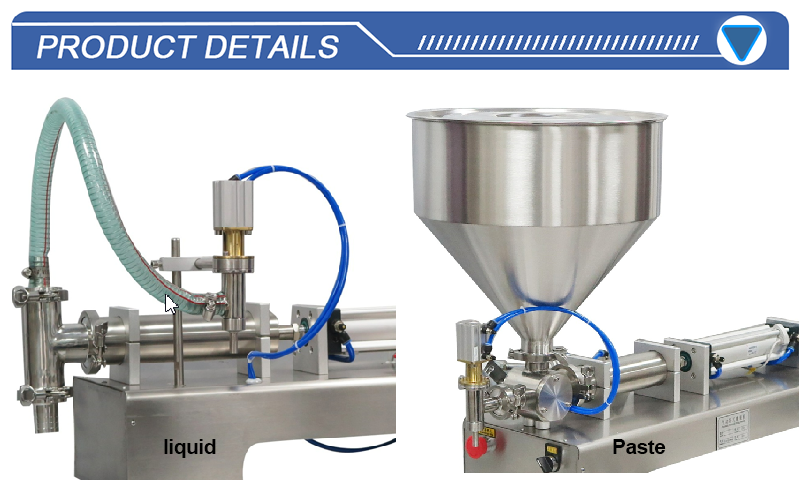

Semi-automatic paste filling machine

The JK-SLF1 semi-automatic paste filling machine offers versatile capabilities for filling liquids and sauces across a wide range of viscosities. With adjustable filling speeds ranging from 4 to 18 bottles per minute and a customizable measuring range from 5ml to 5000ml, it accommodates various product volumes. Powered by a 20KW motor and operating at 220V, it maintains a barometric pressure of 0.4-0.6MPa.

Semi-Automatic Paste Filling Machine

Product Description

The JK-SLF1 semi-automatic paste filling machine is designed for precision filling of various liquids and sauces such as soy sauce, vinegar, edible oil, milk, chili sauce, jam, honey, and wine. With adjustable filling volumes ranging from 5ml to 5000ml and a filling speed of 4-18 bottles per minute, it offers flexibility and efficiency for small to medium-scale production operations. Its compact size, robust construction, and easy operation make it an ideal choice for enhancing filling accuracy and productivity in food processing and packaging industries.

Product Specification

| Model | JK-SLF1 |

| Filling Speed | 4-18 bottles/min (depend on filling volume) |

| Measuring Range | 5-50ml 10-100ml 20-200ml 30-300ml 50-500ml 100-1000ml1500-2500ml 500-3000ml 2000-5000ml Customized |

| Power | 20KW,220V |

| Barometric | 0.4-0.6MPa |

| Machine Size(L*W*H) | 1140*300*530mm |

| Machine Weight | 19-40kg |

Product Features

Versatile Filling Capability: Able to handle a wide range of liquids and viscous sauces, including soy sauce, vinegar, edible oil, milk, chili sauce, jam, honey, and wine.

Adjustable Filling Volume: Measuring range from 5ml to 5000ml, with customizable options to suit various packaging needs.

User-Friendly Design: Compact and easy to operate, requiring minimal training for operators. Simplified controls ensure accurate filling and minimize product wastage.

Barometric Pressure Control: Operates within a controlled barometric pressure range of 0.4-0.6MPa, maintaining filling accuracy and minimizing spillage.

Product Advantages