Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

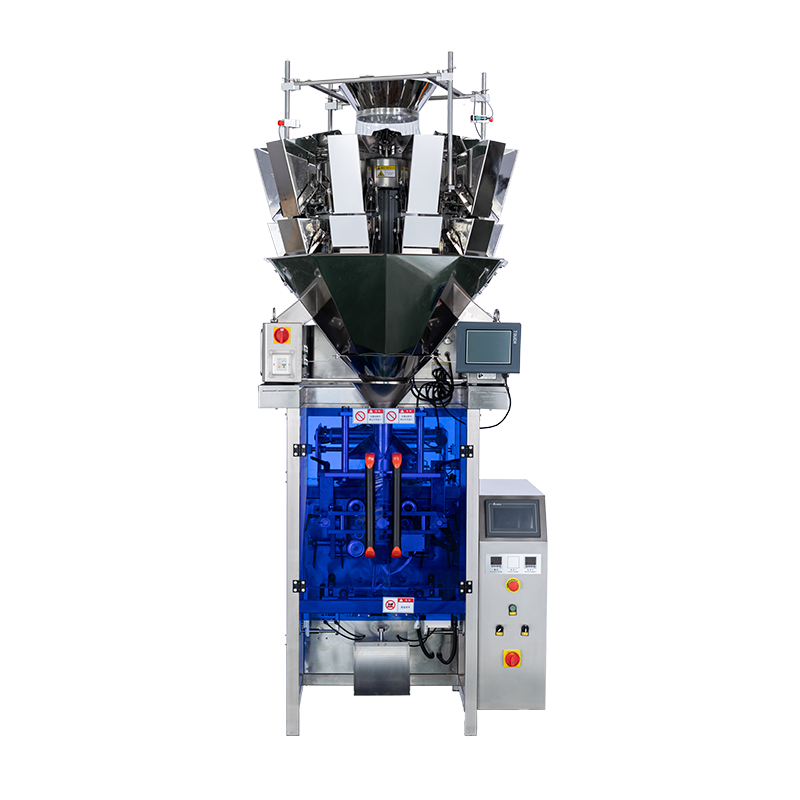

Granule packaging Machine

(13)Granule Packing Machine With Combination weigher

The granule packing machine with combination weigher is designed to revolutionize granule packaging. This innovative equipment combines advanced weighing technology with precision engineering to ensure accurate and efficient packaging of a wide range of granular products. With its high-speed performance and versatile packaging options, it sets a new standard for efficiency and productivity in granule packaging operations.

Simple platform combination weighing packaging machine

The simple platform combination weighing packaging machines offer high precision and efficiency for various packaging needs. The models—JK-C420G, JK-C520G, and JK-C720G—cater to different bag sizes and packing speeds, handling 100-3000ml. They feature a PLC computer control system and servo film transporting for precise operation. The machines automate the entire packaging process, including measuring, feeding, filling, and printing.

Back sealing granule packing machine

The back sealing granule packing machines come in three models to suit various packaging needs. The JK-320GB is ideal for small packages, with a speed of 20-60 bags/min and a measuring range of 2-100g. The JK-380GB handles medium packages at 15-40 bags/min and 50-500g. The JK-480GB is for large packages, operating at 10-30 bags/min and 500-1000g. All models feature 2KW power, 220V, 50Hz, ensuring efficiency and reliability.

Powder packaging Machine

(5)Collar Automatic powder packing machine

The JK-C series collar automatic powder packing machines are versatile solutions for precise and efficient packaging of powdered products. Available in three models—JK-C420P, JK-C520P, and JK-C720P—they accommodate various bag sizes, packing speeds, and measuring ranges to suit different production needs. These machines feature robust construction, ensuring durability and reliability in industrial settings.

Reciprocating Powder packing machine

The JK-R320PB reciprocating powder packing machine, designed for precision packaging of powdered products. With a versatile bag size range of W:30-100mm and L:50-180mm, it efficiently packs from 2 to 100g at speeds ranging from 10 to 60 bags per minute. This machine ensures accuracy and reliability in packaging various powders, supported by a power capacity of 2.8KW at 220V and 50HZ. Compact yet robust, it measures 1100*980*1750mm and weighs 330kg, making it ideal for both small-scale and medium-scale production environments.

Four-side sealing Powder packing machine

The JK-320PF four-side sealing powder packing machine is a versatile powder packing machine designed for efficiency and precision. With a packing speed ranging from 20 to 60 bags per minute and a measuring range of 2-100g, it caters to various packaging needs. The machine features a compact design with dimensions of 880*1200*1750mm and weighs 280kg, making it suitable for different production environments.

Three-side sealing Powder packing machine

The JK-320PT and JK-380PT exemplify the pinnacle of three-side sealing powder packing technology. These machines are designed to automate and streamline the packaging process for a wide variety of powdered products. With a robust and versatile design, they accommodate bag sizes ranging from 30-140mm width and 50-170mm length (JK-320PT) to 80-180mm width and 80-250mm length (JK-380PT), offering flexibility for different packaging requirements.

Liquid packaging Machine

(10)Collar Automatic liquid/sauce packing machine

Our automatic liquid/sauce packing machines are designed to cater to a wide range of packaging needs with precision and efficiency. The models JK-C420L, JK-C520L, and JK-C720L handle different bag sizes and volumes, from small to large, with packing speeds ranging from 5 to 50 bags per minute. Each machine features accurate measurement capabilities, robust performance, and user-friendly maintenance.

Four-side sealing Liquid/sauce packing machine

The JK-320LF is a specialized four-side sealing liquid/sauce packing machine designed for efficient and precise packaging of liquids. It supports a bag size range of W:30-140mm and L:50-180mm, catering to various packaging needs. With a packing speed of 20-60 bags per minute and a measuring range from 2g to 100g, it ensures versatility in packaging small to medium liquid volumes accurately. Its compact design, measuring 880*1350*1750mm and weighing 280kg, optimizes floor space and facilitates integration into production lines.

Reciprocating Liquid/sauce packing machine

The JK-R320LB reciprocating liquid/sauce packing machine is designed to handle a diverse range of packaging needs efficiently. With adjustable bag sizes from 30mm to 100mm in width and 50mm to 180mm in length, it operates at speeds ranging from 10 to 60 bags per minute. This machine offers a measuring range from 2g to 100g, making it ideal for packaging various products such as jelly, konjac, and both oily and water-based seasoning packages.

Fruit board jelly packaging machine

The JK-320LF fruit board jelly packaging machine is a specialized packaging solution designed for efficient and precise packaging of fruit board jellies. It accommodates bag sizes ranging from W:30-140mm to L:50-180mm, making it versatile for various packaging needs. Operating at speeds of 20 to 60 bags per minute, it ensures rapid production output. The machine can accurately measure jelly volumes from 2g to 100g, facilitating precise measuring and packaging. Powered by a 2.2KW, 220V, 50Hz system, it balances energy efficiency with performance.