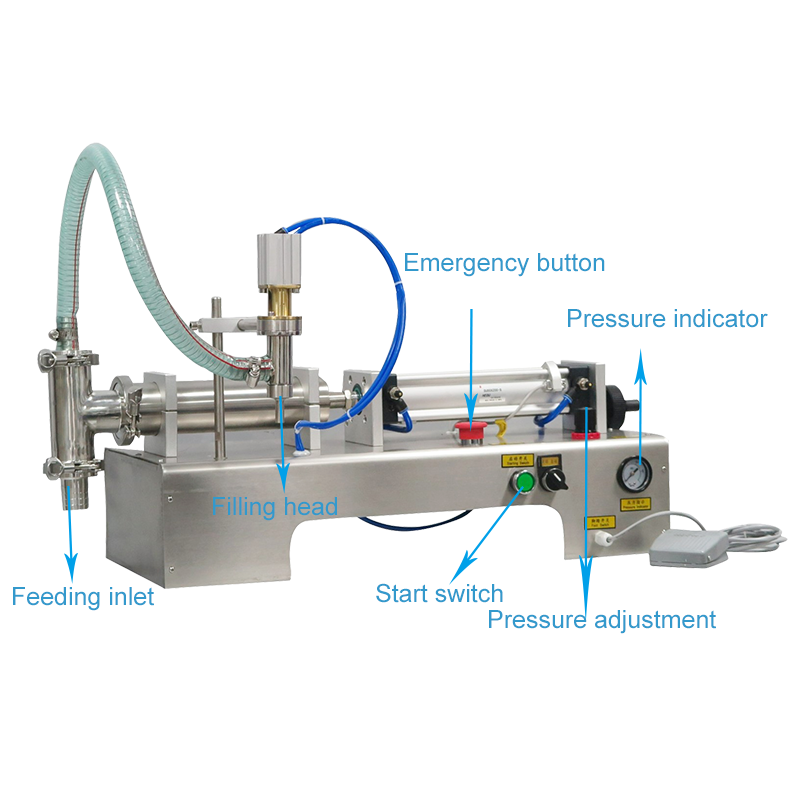

Ease of Operation and User-Friendly Design: The semi-automatic liquid filling machine features straightforward controls and an intuitive design that simplify operation. Intuitive interfaces and clear labeling of controls enhance usability, allowing operators to quickly adjust settings for different liquids or bottle sizes.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Semi-automatic liquid filling machine

The JK-SLF1 semi-automatic liquid filling machine is designed for versatile liquid filling applications. With a filling speed ranging from 4 to 18 bottles per minute, depending on the volume, it accommodates a wide measuring range from 5ml to 5000ml, including customized options. Powered by 20KW at 220V and barometric pressure of 0.4-0.6MPa, it is suitable for filling liquids such as water, wine, milk, edible oil, flavor drinks, and vinegar products.

Semi-Automatic Liquid Filling Machine

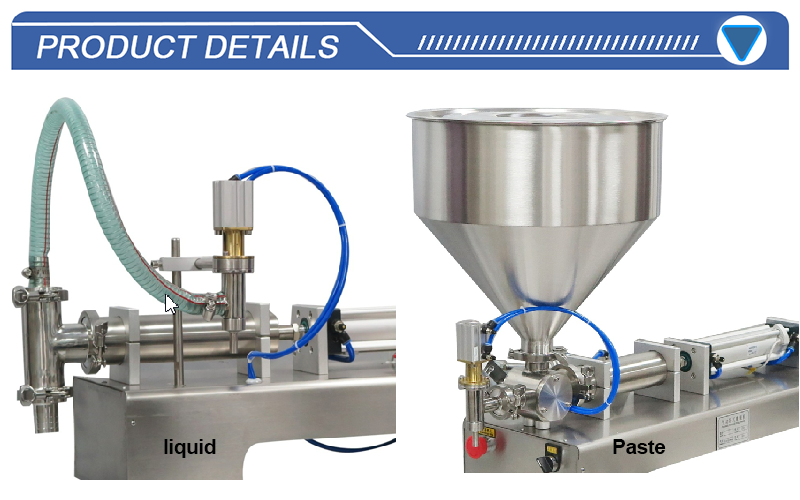

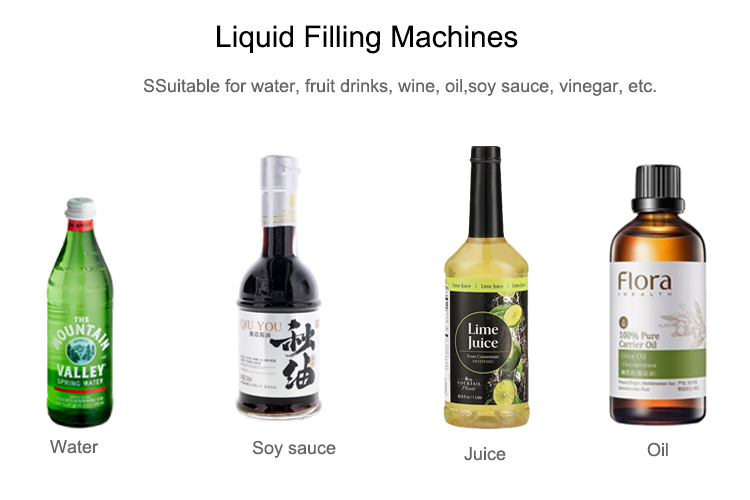

Product Description

The semi-automatic liquid filling machine is a versatile equipment designed for filling various types of liquids such as water, wine, milk, edible oil, flavor drinks, and vinegar products. It offers adjustable filling speeds ranging from 4 to 18 bottles per minute, depending on the volume being filled. With a broad measuring range from 5ml to 5000ml, including customized options, and powered by 20KW at 220V, it combines efficiency with flexibility. Compact in size (1140300530mm) and lightweight (19-40kg), it is suitable for small to medium-scale production environments requiring precise and reliable liquid filling capabilities.

Product Specification

| Model | JK-SLF1 |

| Filling speed | 4-18 bottles/min (depend on filling volume) |

| Measuring range | 5-50ml 10-100ml 20-200ml 30-300ml 50-500 ml 100-1000ml1500-2500ml 500-3000ml 2000-5000ml Customized |

| Power | 20KW,220V |

| Barometric | 0.4-0.6MPa |

| Machine size(L*W*H) | 1140*300*530mm |

| Machine weight | 19-40kg |

Product Features

Barometric Pressure Control: Includes a barometric pressure range of 0.4-0.6MPa to maintain consistent filling performance across different liquid viscosities.

Customization Options: Provides flexibility with customizable filling volumes (from 1500ml to 2500ml and beyond), catering to specific production requirements.

Cost-Effective: Helps reduce labor costs and improve operational efficiency by automating the filling process while optimizing material usage.

Product Advantages

Accurate Filling with Precision Control: This machine ensures precise measurement and filling of liquids, contributing to minimal product wastage and consistent product quality. It employs reliable mechanisms and sensors to control the filling process, ensuring that each bottle receives the exact volume of liquid required.

Compact Size for Efficient Space Utilization: Designed with a compact footprint, the semi-automatic liquid filling machine occupies less floor space compared to fully automated systems. This compact size makes it well-suited for smaller production environments or facilities with limited space. Despite its smaller footprint, the machine retains high efficiency and functionality, making it an ideal choice for businesses looking to maximize their operational efficiency without compromising on performance.