Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

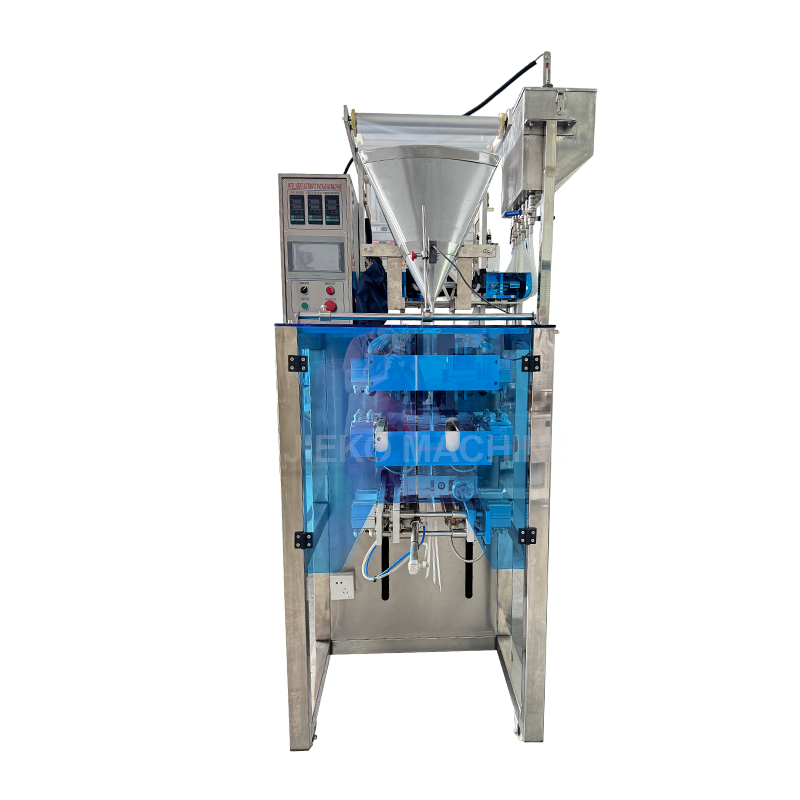

Automatic liquid honey packaging machine multiple rows 1 out of 6

Multi-lane Liquid Packing Machine

Product Description

JK-480LF four-side seal multi-lane liquid packaging machine. It can accommodate packaging bag sizes ranging from W:20-60mm to L:50-220mm, which can meet various packaging needs. The machine can produce 60-150 bags per minute and can complete 6 packs at a time, improving production efficiency. The machine is powered by a 2.2KW, 220V, 50Hz system, with high efficiency and extremely low energy consumption.

Product Specification

| Model | JK-480LF |

| Packing speed | 60-150 Bags/Min |

| Bag size | L:50-220mm W:20-60MM |

| Maximum packing film width | 480MM |

| Film roll diameter | 400mm |

| Power | 220V, 2.2KW, 50/60HZ |

| Product Dimension | 1560*1100*2310mm |

| Gross weight | 500kg |

Product Features

High Packing Speed: Operates at speeds ranging from 60 to 150 bags per minute, ensuring efficient production output.

Four-Side Sealing Design: Provides secure and tamper-evident packaging, ensuring product integrity and freshness.

User-Friendly Interface: Features intuitive controls for easy operation and adjustment of packaging parameters.

Product Advantages

Built with High-Quality Materials and Robust Engineering to Withstand Demanding Food Environments: These machines are constructed using robust materials such as stainless steel and high-quality engineering plastics, ensuring they can withstand the rigors of food environments. This durability minimizes the risk of wear and tear, contributing to long-term reliability and reducing downtime for maintenance.

Meeting Stringent Regulatory Requirements for Food Safety, Hygiene, and Quality Assurance to Ensure Consumer Safety: Four-side sealing liquid/sauce packing machines adhere to strict regulatory standards for food safety, hygiene, and quality assurance. Compliance ensures that packaged liquids maintain their safety, integrity, and quality throughout the production and distribution chain.

Streamlining Operations Through Automation to Minimize Reliance on Manual Labor and Enhance Efficiency: These machines automate the liquid packaging process, significantly reducing the need for manual labor. Automation minimizes human error associated with manual packaging, ensuring consistency and accuracy in product packaging.