Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Back Sealing Packing Machine Company: The Ultimate Guide to Choosing the Right Partner

In the fast-paced world of packaging, back sealing packing machines have become an essential tool for businesses across industries. These machines are designed to streamline packaging processes, enhance efficiency, and ensure product integrity. If you’re looking for a back sealing packing machine company to partner with, understanding the market and what to look for is crucial.

This blog will explore everything you need to know about these companies, including the benefits of back sealing packing machines, how to select the right company, and the key features to look for in a machine.

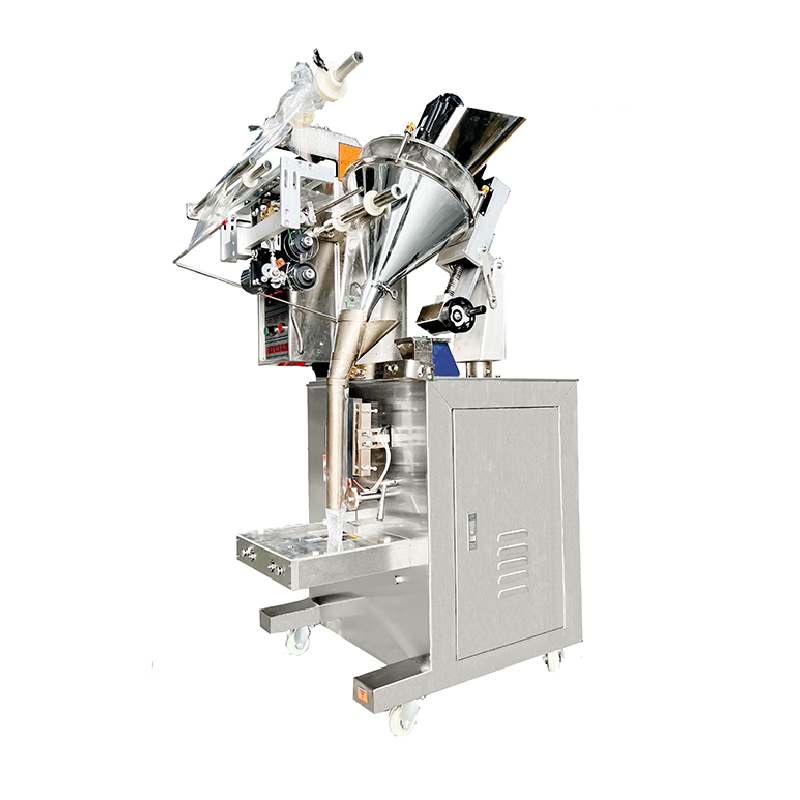

What Are Back Sealing Packing Machines?

Back sealing packing machines are versatile equipment that package products by sealing the back of the material. This type of sealing is common in industries such as food, pharmaceuticals, and chemicals. The machines are particularly effective for granules, powders, and liquids.

These machines ensure:

- Seamless packaging to prevent leaks or contamination.

- Enhanced aesthetics, with clean, professional-looking seals.

- Increased efficiency, especially for high-volume production lines.

Why Choose a Back Sealing Packing Machine Company?

Collaborating with a specialized back sealing packing machine company provides numerous advantages:

- Expertise: Companies focusing on these machines have a deep understanding of the technology.

- Customization: Many offer tailored solutions to fit your specific product and packaging requirements.

- Support Services: From installation to maintenance, specialized companies ensure smooth operations.

By choosing the right partner, you can optimize your packaging processes and achieve a competitive edge.

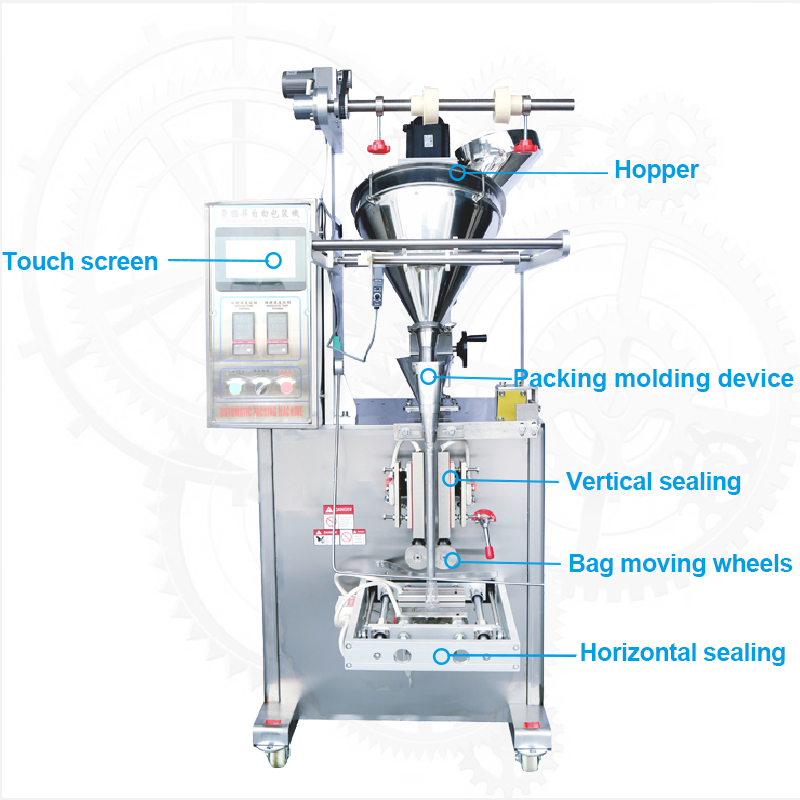

Key Features to Look for in a Back Sealing Packing Machine

When selecting a back sealing packing machine, consider the following features:

1. Material Compatibility

Ensure the machine can handle a variety of materials, such as plastics, paper, or laminates. This flexibility is vital if your product line includes different packaging types.

2. Speed and Efficiency

Look for machines with high-speed capabilities to meet your production demands. A reliable back sealing granule packing machine export model, for instance, should combine speed with precision.

3. Ease of Use

Modern machines often come with user-friendly interfaces, such as touchscreens, that allow operators to control settings easily.

4. Durability and Maintenance

Invest in machines made with high-quality materials to ensure longevity. Opt for companies that provide maintenance support to minimize downtime.

5. Compliance with Standards

Packaging machines should meet industry standards and certifications to ensure safety and quality.

How to Choose the Right Back Sealing Packing Machine Company

Selecting a partner is a critical decision. Here’s what to consider:

1. Industry Experience

Choose a company with a proven track record. Experienced companies often have extensive portfolios and a solid understanding of market needs.

2. Customization Options

Look for companies that offer tailored solutions. Whether you need modifications for a specific product size or material, customization can be a game-changer.

3. After-Sales Support

Packaging machines require regular maintenance. Ensure the company provides robust after-sales services, including training, spare parts, and technical support.

4. Reputation and Reviews

Research customer reviews and testimonials to gauge the company’s reliability. Positive feedback often indicates strong performance and customer satisfaction.

Applications of Back Sealing Packing Machines

These machines are used in a variety of industries, including:

1. Food and Beverage

Back sealing packing machines are ideal for granules like sugar, salt, and coffee, as well as liquids like sauces and oils.

2. Pharmaceuticals

In the pharmaceutical sector, these machines ensure sterile and secure packaging for powders, tablets, and capsules.

3. Chemicals

For products like fertilizers or cleaning agents, these machines provide leak-proof and durable packaging solutions.

The Future of Back Sealing Packing Machines

The packaging industry is evolving rapidly, with innovations shaping the future of back sealing packing machines. Key trends include:

1. Automation and AI

Many machines now feature AI-driven controls, allowing for smarter, more efficient operations.

2. Eco-Friendly Packaging

Sustainability is a growing concern. Back sealing machines are adapting to handle biodegradable and recyclable materials.

3. IoT Integration

IoT-enabled machines allow for real-time monitoring and diagnostics, ensuring maximum uptime and efficiency.

Partnering with the Best: A Strategic Decision

Collaborating with a leading back sealing packing machine company can transform your packaging operations. By investing in state-of-the-art machines and a reliable partner, you’ll ensure consistent product quality, streamline production, and position your business for growth.

Take your time to evaluate companies based on their experience, offerings, and customer support. The right choice will provide long-term benefits and a strong return on investment.

Conclusion

The demand for efficient and versatile packaging solutions is only growing, making back sealing packing machines a vital asset for modern industries. Whether you’re in food, pharmaceuticals, or chemicals, choosing the right back sealing packing machine company is essential.

By focusing on the factors discussed in this guide—such as machine features, company expertise, and emerging trends—you can make an informed decision that aligns with your business goals. Partner with a company that values innovation, quality, and customer support, and watch your packaging process reach new heights.