Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Automatic Three-Side Sealing Machine Herb Tea Powder Packing Machine: Transforming Efficiency and Quality in Packaging

When it comes to packaging solutions for herbal tea powders, efficiency and quality are paramount. The Automatic Three-Side Sealing Machine Herb Tea Powder Packing Machine is designed to meet these demands, providing a seamless, high-speed solution for packaging. This machine ensures that every pouch maintains optimal freshness, and its versatility suits a range of tea blends and powdered substances. In this blog post, we’ll delve into the unique features, benefits, and applications of this specialized packing machine and why it’s becoming a top choice in the food and tea industries.

What is the Automatic Three-Side Sealing Machine Herb Tea Powder Packing Machine?

The Automatic Three-Side Sealing Machine Herb Tea Powder Packing Machine is an advanced packaging machine developed specifically for herbal tea powders and other fine, powdery substances. This machine automates the packing process, forming each pouch, filling it with the required product amount, and sealing it efficiently. Its three-side sealing feature creates durable, secure pouches, which are ideal for preserving the freshness of delicate herb tea powders.

Key Components of the Packing Machine

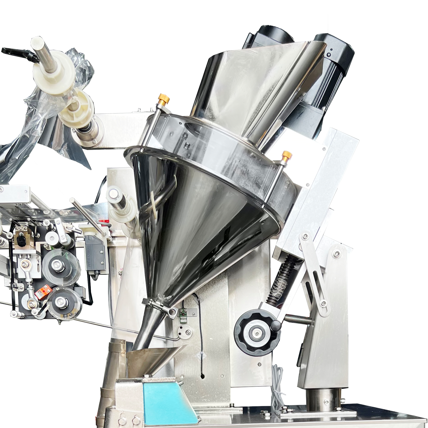

This machine comprises several core components:

- Filling System: Precisely measures and dispenses the herb tea powder into each pouch.

- Sealing System: Delivers a firm three-side seal, ensuring the pouches are tamper-proof.

- Cutting Mechanism: Separates each pouch neatly, delivering a consistent product shape.

- Touchscreen Control Panel: Provides user-friendly control over settings such as pouch size, sealing temperature, and filling quantity.

How the Automatic Three-Side Sealing Machine Works

This machine follows a streamlined, automated process that reduces manual labor and minimizes error. Here’s a closer look at the steps involved:

- Material Feeding: The machine’s hopper feeds herb tea powder to the filling system.

- Pouch Formation: Film material unwinds and forms a pouch, which is prepared for filling.

- Powder Filling: The filling system dispenses the right quantity of powder into each pouch.

- Sealing: The three-side sealing system creates a secure seal around each filled pouch.

- Cutting and Dispensing: The machine cuts each pouch, making them ready for storage or distribution.

This automated process enhances packaging speed, accuracy, and consistency.

Key Benefits of Using the Automatic Three-Side Sealing Machine Herb Tea Powder Packing Machine

1. Enhanced Efficiency

Automation means fewer human hands are needed, which allows for uninterrupted production cycles. Whether you need to package hundreds or thousands of pouches daily, this machine offers a sustainable, efficient solution.

2. Precision in Powder Packing

With accurate filling technology, this machine ensures each pouch receives the precise amount of herb tea powder. This consistency not only improves quality control but also reduces material waste.

3. Extended Product Shelf Life

The three-side seal effectively locks in freshness, preventing exposure to air, moisture, or contaminants. This feature is crucial for herb tea powders, which require careful preservation to maintain their aroma, flavor, and potency.

4. Easy Customization

The machine allows easy customization of pouch size, powder quantity, and sealing strength, enabling businesses to adapt to different product requirements without changing the equipment setup.

Applications of the Automatic Three-Side Sealing Machine Herb Tea Powder Packing Machine

While the primary use of this packing machine is for herb tea powders, it can also package other fine powders and similar materials. Some popular applications include:

- Herbal Powders and Supplements: Ideal for producing small, single-use pouches of herbal supplements.

- Flour and Spice Powders: Works well with fine flour blends and spice powders.

- Health and Wellness Products: Commonly used in packaging powdered superfoods and nutritional supplements.

This machine’s versatility makes it an invaluable tool for businesses operating in the health, wellness, and food industries.

Choosing the Right Automatic Three-Side Sealing Machine for Your Needs

To find the best fit, it’s essential to consider the specific requirements of your production environment. Here are a few factors to keep in mind:

1. Production Capacity

Consider your daily output requirements. If you operate a high-volume production line, select a machine that can handle large quantities without compromising quality.

2. Sealing Quality

Three-side sealing machines vary in seal strength, so ensure the machine you choose can achieve a durable, high-quality three-side sealing powder packing machine standard. This will help maintain product freshness and prevent spillage.

3. Powder Type and Flowability

The machine’s filling system should match the characteristics of your powder. Herb tea powders vary in flowability, so it’s wise to test the machine with your specific product before investing.

4. Ease of Maintenance

Opt for a machine that’s easy to clean and maintain, as this can significantly affect production uptime and machine longevity.

Industry Standards and Compliance: A Key Factor in Choosing a Packing Machine

Ensuring compliance with food-grade and safety standards is vital for businesses packaging edible products. The machine typically meets international safety and quality standards, such as:

- GMP Compliance: Ensures good manufacturing practices are followed.

- FDA Standards (for Food Safety): Essential for companies packaging consumables.

- ISO Certifications: Offers reassurance of consistent quality management.

Investing in a machine that aligns with these standards can protect your business from regulatory issues and help build consumer trust.

Cost Efficiency: A Long-Term Investment for Growing Businesses

While an Automatic Three-Side Sealing Machine Herb Tea Powder Packing Machine requires an initial investment, the benefits of cost savings over time make it worthwhile. Here’s how:

- Reduced Labor Costs: Automation reduces the need for manual labor, saving on wages and training expenses.

- Minimized Product Waste: Precision filling minimizes powder wastage, which lowers material costs.

- Lower Maintenance Costs: High-quality packing machines are designed to operate efficiently with minimal repairs, reducing long-term maintenance costs.

For companies planning to scale, this machine offers an efficient path to growth without the need for frequent equipment upgrades.

Maintenance Tips for Your Packing Machine

Regular maintenance is essential to ensure that the packing machine remains in optimal working condition. Here are a few key maintenance tips:

- Daily Cleaning: Remove any powder residue and clean the filling and sealing areas to prevent clogging.

- Regular Lubrication: Lubricate moving parts as specified by the manufacturer to maintain smooth operation.

- Routine Inspections: Check for signs of wear and tear on seals and replace any worn components promptly.

By following these practices, you can ensure your machine continues to perform efficiently and reliably.

Conclusion: The Future of Herbal Tea Powder Packaging

The Automatic Three-Side Sealing Machine Herb Tea Powder Packing Machine exemplifies innovation in the field of packaging. Its combination of speed, precision, and high-quality sealing makes it a valuable asset for businesses in the herbal tea and wellness industries. As demand grows for efficient, scalable, and sustainable packaging solutions, machines like this are expected to become essential in production lines worldwide.

With its ability to deliver high-quality, consistent packaging, the Automatic Three-Side Sealing Machine for herb tea powders not only streamlines operations but also enhances product quality and consumer satisfaction.